The rise of advanced technology and engineering has led to a revolutionary manufacturing sector. With the shift to digitalization and the rapid growth of digital infrastructure, it’s no surprise that more and more industries are beginning to reap the benefits of innovative tech. Cloud computing has allowed us to virtualize operations, streamline tasks, and securely enter a new era. The manufacturing industry has already surpassed other industries in terms of cloud adoption. With the use of manufacturing automation, companies can save time and effort while drastically reducing human errors. Around 32% of the manufacturing sector can already be classified as “cloud leaders.” One of the strongest driving forces in the modernization of the manufacturing sector has been the interest in automation systems. According to Statista, the global industrial automation market size is expected to grow to US$ 265 billion in 2025.

What Is Manufacturing Automation?

Manufacturing automation is quite exactly what it sounds like – the automation of the manufacturing process. The process is streamlined and efficient. Manufacturing automation uses software or robotic process automation to carry out previously manual processes in a factory to produce a physical product without human intervention. This involves processing, assembly, inspection, inventory management, and production planning techniques.

The automation of processes in manufacturing is typically met with a mix of fear and excitement. While the innovative new technology can be exciting to streamline tasks, there can be fears that the automating robots will replace the human workforce. However, the automated processes are usually monotonous, dirty, or unsafe for humans to handle alone. These robots can lift heavier weights, work quickly, and protect human lives from dangerous or exhausting tasks.

Industry Examples of the Automation in Manufacturing Process

Naturally, automation in manufacturing industry sectors has skyrocketed in the digital age. More companies are looking at different types of automation to streamline operations, boost productivity, and create a tangible difference in the industry for workers and customers alike. The International Federation of Robotics has reported that there are currently around 3.5 million industrial robots in operation globally. Some of the main manufacturing industries that have benefited from robotic process automation so far include:

Automotive Industry

Automation in car manufacturing is possibly one of the biggest examples of automation in the manufacturing sector. Technavio has predicted that the automation market size in the automotive industry is estimated to grow by US$ 1.95 billion from 2021 to 2026. Car manufacturing requires a lot of hard labor and the movement of heavy parts and technical aspects – especially with the emergence of electronic cars. Automation can help streamline assembly lines by providing welding, polishing, assembling, and other processes. Some of the major automotive companies operating in the automation market include: Ford, General Motors, Mercedes-Benz, and BMW.

Electronics Manufacturing

The manufacturing of electronics can be challenging already. Complex technical aspects make the creation of smaller circuit boards and other increasingly complicated components difficult for human hands. Automation can be useful for streamlining operations and increasing production of electronics for a growing market. It also helps with quality testing, assembly, delicate handling, and more. Examples of automated electronic companies include: Emerson Electric Co., Pegatron, Quanta, Siemens, and Wistron.

Food and Beverage Industry

The production process for food and beverages needs to be heavily optimized and precise. Providing food for supermarkets and consumers requires dedication to food safety protocols, efficient packaging, and streamlined processes. Automated functioning can offer quick and easy labeling, stacking, packing, and more for the food industry. Examples of automated food industry companies include: Nestle, Sysco Corporation, and Cargill.

Logistics

Logistics companies are necessary to keep the supply chain running and production going smoothly across almost all industries. Automation of the delivery of services and goods includes finding ways to deliver faster, cheaper, and more efficiently. It also helps with inventory management for companies and customers to track products and delivery locations. Examples of logistics companies using automation include: Daifuku, KION Group, Locus Robotics Corp., Dematic, and Honeywell International, Inc.

Use Cases of Automation in Manufacturing

Implementing RPA – or Robotic Process Automation – is no new concept for most growing and established brands. Automation in manufacturing has always been a key element to producing better results in a shorter amount of time. According to Medium, a leading robot manufacturer in Japan called FANUC uses its automated industrial robots to create over 22,000 new robots per month for customers such as Apple, Tesla, and other companies.

Tesla took automation to new levels when it launched its electric car range. Elon Musk, the owner of the company, settled on a fully automated production strategy. Going even further, Musk has used cloud computing and AI to maintain his autonomous self-driving cars.

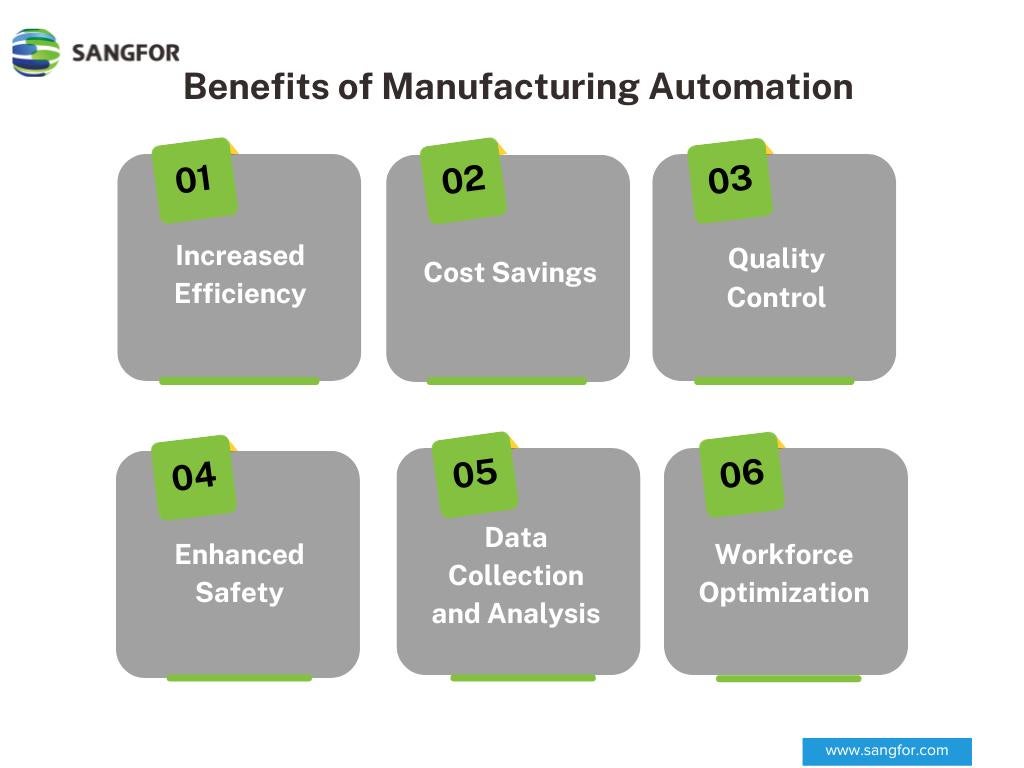

Benefits of Manufacturing Automation

With process automation, companies enjoy an array of advantages. Some of the main benefits of automation in manufacturing include:

- Increased Efficiency: The main reason for automation is the efficient manufacturing process. Automated processes save time and energy while boosting production, invoice processing, and lead time. These machines can operate at a much faster rate with fewer errors.

- Cost Savings: Automation in manufacturing also reduces the expenses of a company. While producing more efficient results, automation also lowers labor costs, production wastage, and the risk of downtime.

- Quality Control: Product quality is one of the main concerns for any manufacturer. If the production quality is low, the entire company will suffer. With automation, almost all production lines are of the highest quality. Automated robotic processing ensures consistent and reliable output each time.

- Enhanced Safety: Manufacturing can be a hazardous industry. Most factory workers are constantly putting their bodies and lives at risk to work in dangerous, cramped, and suffocating workspaces. The use of robotic process automation in manufacturing ensures elevated safety for your workforce by taking on these tasks instead. The lifting of heavy objects, handling of dangerous chemicals, or generally tedious tasks can all be handled by the robots.

- Data Collection and Analysis: Any manufacturing company relies on feedback and data to calculate costs and make improvements. Automation also makes it easier to scan inventory levels, collect data, and generate analysis reports.

- Workforce Optimization: Your workforce can produce better results with the help of automated systems. Rather than replacing human jobs, these machines simply make these jobs easier and improve worker retention, satisfaction, and drive.

The Future of Automation in Manufacturing

When considering the future of automation in manufacturing, you need to look at how innovative technologies have already changed us in the past. With every new technology, we have raced to keep ahead and stay on top. We’ve rounded up some of the most impressive technologies that have helped automation in manufacturing thrive:

Collaborative Robots (Cobots)

These are physical robots that help an existing human workforce in production. The collaborative robot is responsible for the more repetitive and menial tasks while a human worker completes more complex and thought-intensive tasks. The cobots market is expected to reach US$ 7.5 billion in value by 2027. They can be deployed across industries and can help with several tasks. Some of the successful cobots already in use include: Comau for Smart Factories, Singrow for Agriculture, UR20 for Small Industrial Spaces and Bossa Nova Robotics for Retail.

Artificial Intelligence (AI) and Machine Learning

As AI increases in popularity and use, the automated manufacturing sector could use its help to produce better results. According to Deloitte, 93% of companies already believe that AI will be a “pivotal technology to drive growth and innovation” in manufacturing. With its advanced and evolving uses, AI can be crucial to creating intelligent automation. With AI, manufacturing automation can:

- Detect errors.

- Identify patterns quickly.

- Suggest improvements.

- Understand complex tasks.

Internet of Things (IoT) Integration

The Internet of Things (IoT) is a vastly growing network of devices that collect and share data. As it grows, it can be useful for manufacturing automation by providing intelligent processing power and enhanced digitalization for tasks. Research has shown that the IoT in manufacturing market size is projected to grow to US$ 53.8 billion by 2025. Harley-Davidson is one of the companies that used IoT to reconfigure its production and improve its manufacturing facilities layout – reducing the total time of creating one motorbike from about 3 weeks to 6 hours. The IoT can help automated manufacturing by:

- Connecting devices and sensors to exchange data faster.

- Providing real-time scheduling.

- Generating reports based on collected data to improve productivity.

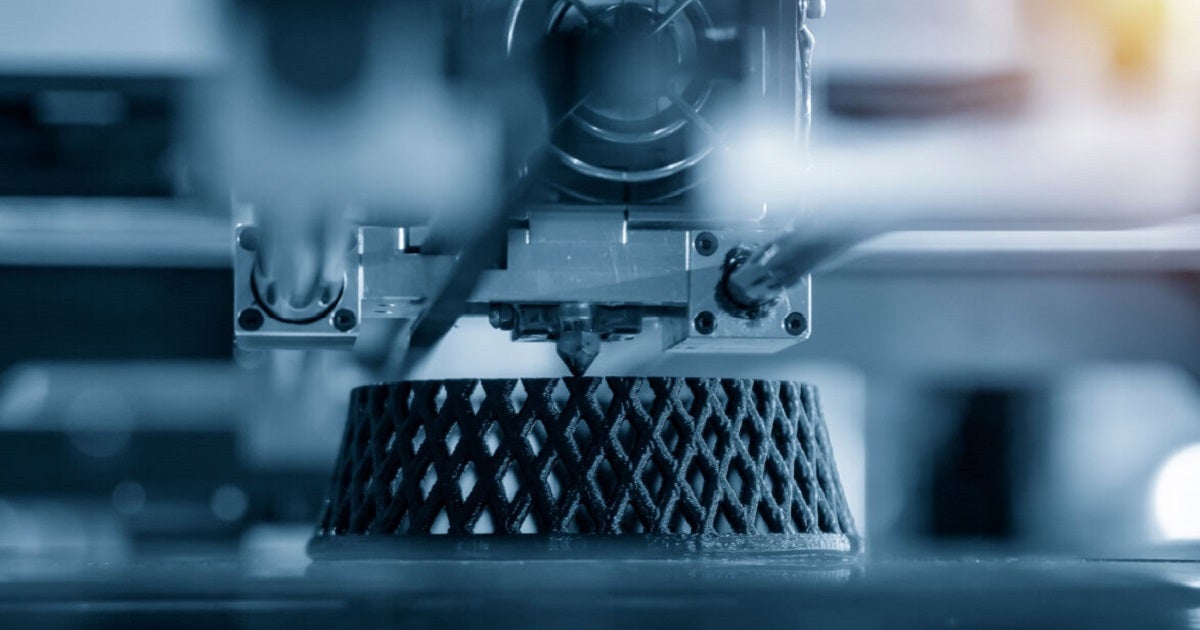

3D Printing or Additive Manufacturing

3D printing is a software-driven form of additive manufacturing that can generate physical products by laying down successive layers of material and fusing them. While some people have concerns that it can replace manufacturing entirely, it can be useful as a tool in the automated production process. With 3D printing, you can create specific items for your product in a much smaller amount of time. Some companies that use 3D printing for manufacturing include Volkswagen and L’Oreal.

Autonomous Mobile Robots (AMRs)

These are robots that operate autonomously while finding their way around uncontrolled environments - without the need for fixed paths or tracks. AMRs are known for flexibility and intelligent navigation skills. They can play a large role in automated manufacturing through their use of cameras, sensors, laser scanners, and sophisticated software to construct maps. This is useful for:

- Transporting heavy materials or objects.

- Repetitive tasks.

- Detecting and avoiding obstacles.

- Ensuring production flow.

Virtual and Augmented Reality

Virtual reality is an impressive new technology that has taken the world by storm. For the automated manufacturing industry, virtual reality can help with training and development to help your workforce apply their skills without any risks. Ford successfully demonstrated this use of virtual reality when it partnered with Bosch to provide technicians with a new virtual reality (VR) training tool. The company maintained that the virtual reality training solution is about new technology that builds efficiency. Geoff Mee, the director of operations for Bosch, said that “by improving the diagnostic process, technicians can perform maintenance and make repairs faster and more easily.” Other companies that used VR to improve manufacturing capabilities include: General Electric and Lockhead Martin.

Cloud Computing and Big Data Analytics

Manufacturing Automation requires and produces large amounts of data daily. This data is crucial to creating better products, evaluating production value, and elevating your company. This is why more major automated manufacturing companies are turning to cloud computing platforms and big data analysis to store, process, and protect their data. Cloud Infrastructure offers a range of advantages for any automated manufacturing company, including scalability, security, and flexibility.

Energy Efficiency and Sustainability

Automation in manufacturing is also crucial to sustainable production. With the use of automated machines, your wastage is cut down drastically – removing a chunk of the burden on the environment. The highly efficient, flexible, and streamlined processes also mean that fewer energy resources are used and your carbon footprint is reduced. Some of the ways automated manufacturers improve sustainability include:

- Efficient machines require less heating.

- Less wastage.

- Reduced cycle times mean less energy is used.

- Robots require less factory space.

Automation in manufacturing is a brilliant way to streamline processes and production lines across several industries. As we move further into the modern age, we should look to these innovative technologies to elevate the way we work, live, and create in the future.

For more information on Sangfor’s cybersecurity and cloud infrastructure solutions, please visit www.sangfor.com.